From one off prototypes to high volume mass production, Titan Advanced Manufacturing can help!

Our capabilities include:

Milling – up to 5 axis with integrated scheduling and lights-out capability

Turning – up to 7 axis live tooling, bar feeder, and automated part management. Able to create quick-turn prototypes through full-rate production.

Full DCC Coordinate Measuring Machine (CMM) with scanning

Complete Quality Control Lab with calibrated tools per ISO17025, ANSI-Z540 calibration, and AS9102 FAIs capability.

Managed supply of various plating, inspection, testing, thermal, and other 2nd processes FAR, DFAR, FAA, FDA, DOT, ITAR, REACH & RoHS Compliance

HAAS UMC 500

MILL

15,000 RPM x 30 HP HSK Spindle

High Speed Machining

1200 IPM cutting speeds

2000 IPM Rapids

Through Tool High Pressure Coolant

20 Station Pallet Pool

5 Axis Milling

Automatic tool setter

Renishaw probing

70 + 1 tool carousel

X=20”, Y=16”, Z=16”

Full 360° C axis & 135° full tilt in B

Capable of complex prototyping or high efficiency in full rate production

HAAS VF1

MILL

12,000 RPM x 30 HP Spindle

High-Speed Machining

900 IPM cutting speeds

1200 IPM Rapids

High-Pressure Coolant

4.5 Axis Milling with Rotary and 90° Heads

Universal Fixtures

Quick Change Over

X= 24” Y=18” Z=20”

360° 4th Axis

Various angle head options

Capable of complex prototyping, second operation milling, and quick turn short run production

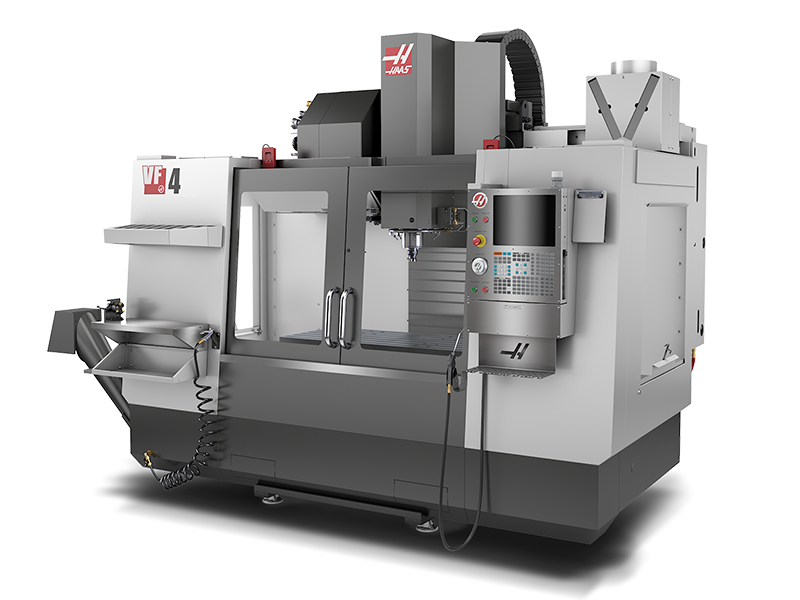

HAAS VF4

MILL

8,100 RPM x 30 HP Spindle

High-Speed Machining

650 IPM cutting speeds

1000 IPM Rapids

Liquid Coolant

4.5 Axis Milling with Rotary and 90° Heads

Universal Fixtures

Quick Change Over

X= 50” Y=20” Z=25”

360° 4th Axis

Various angle head options

Capable of complex prototyping, second operation milling, and quick turn short run production

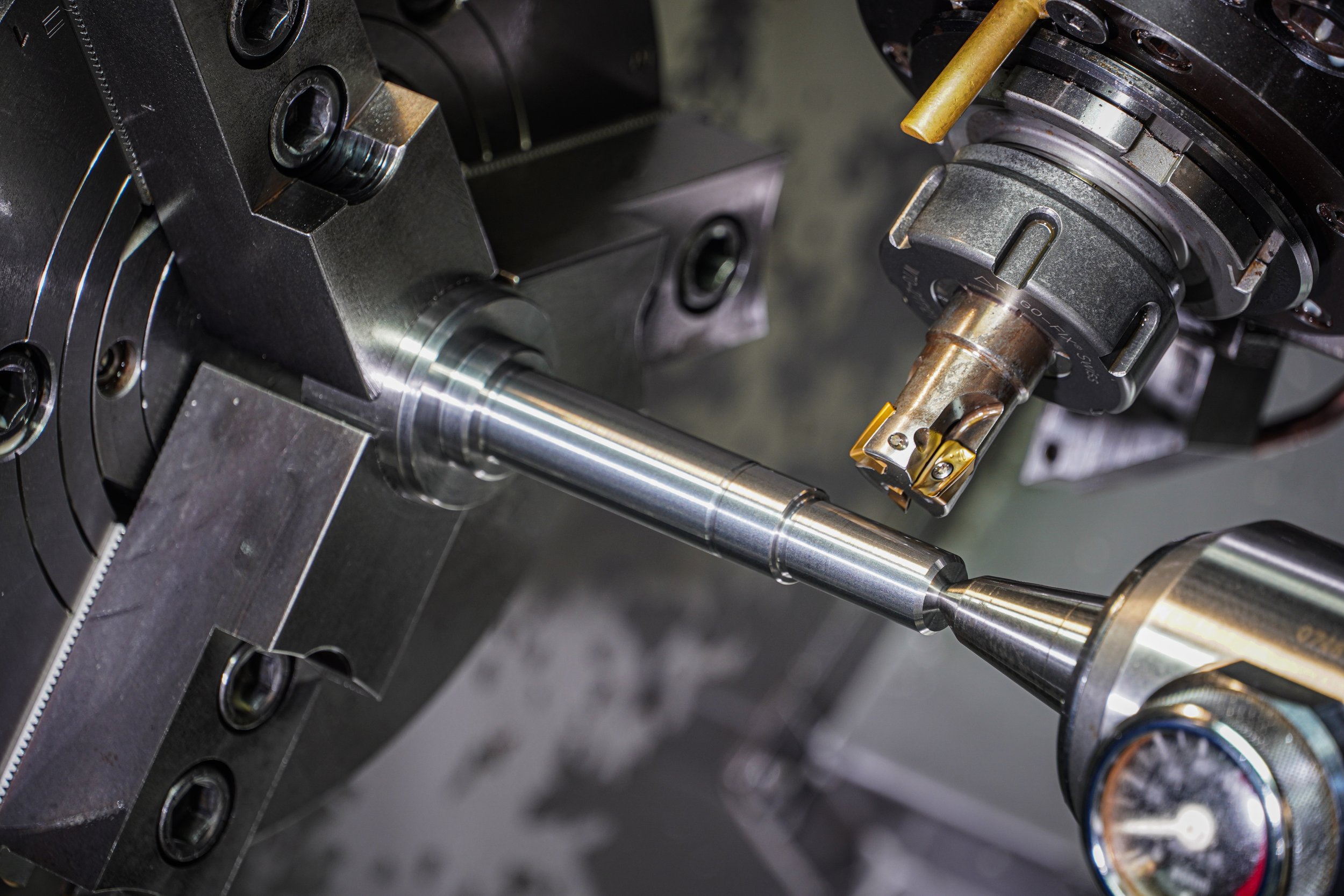

HAAS DS30SS

LATHE

Main 30HP Spindle 4800 RPM

Sub 30HP Spindle 4800 RPM

Synchronous Handoff main to sub

24 turning tools

12 rotary tools

Bar feeder with 3.0” through bore

Parts Catcher

Tool Presetting arm

High Pressure coolant

Turn Dia 16”

Max Length 26”

Capable of complex prototyping and high efficiency production

HAAS ST20

LATHE

20HP, 4000RPM Spindle

24 turning tools

12 rotary tools

Bar feeder with 2.5” through bore

Parts Catcher

Tool Presetting arm

High Pressure coolant

Max Dia 13”

Max Length 22.5”

Capable of complex prototyping, high efficiency production, and quick turn short run production

Tsugami SS32

LATHE

200 – 8,000 RPM Spindle Speed

24/40 Tool Positions (std / max)

6 Axes

320 mm, 12.6” Stroke easily handles long pieces

Handles Complex Parts

Large Tool Zone

Fanuc 32i-B CNC

Change part runs quickly, handle long and short run jobs easily. Live tools moved at will!

Sheffield 9.12.7 CMM

INSPECTION

Full DCC control

TP 20 Renishaw probing head

10 station probe rack

Controlled with CMM Manager

Floating air bearings

Universal or dedicated fixturing

Positional tolerance .00004”

Linear Accuracy .00002”

Communication with InspectionXpert

Mitutoyo 15” Optical

INSPECTION

Up to 50X magnification

Surface Illumination

DRO with X,Z and Rotational Feedback

M3 Measuring Software

Touch Screen

Programmable

Able to communicate with InspectionXpert