From one off prototypes to high volume mass production, Titan Advanced Manufacturing can help!

Our capabilities include:

Milling – up to 5 axis with integrated scheduling and lights-out capability

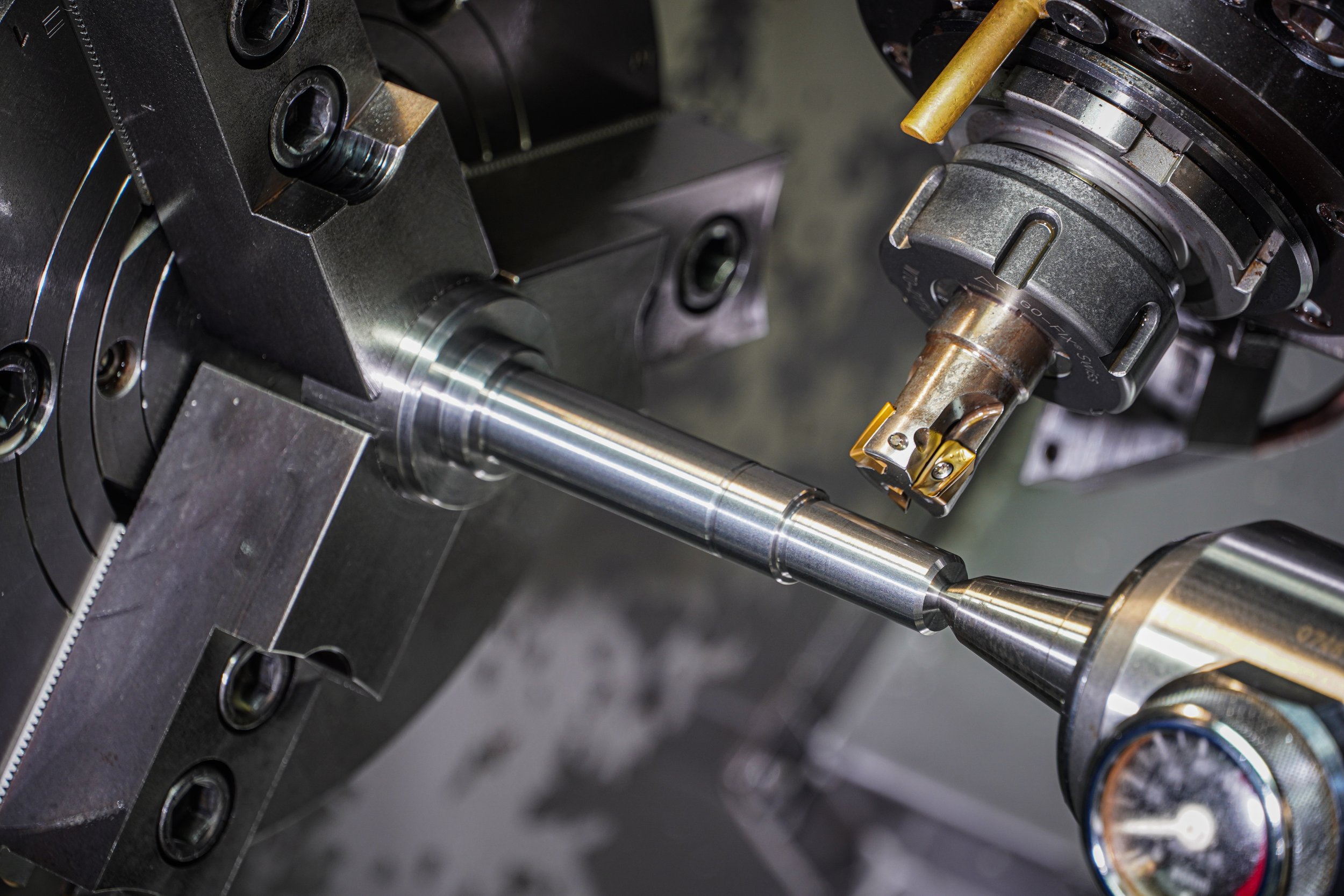

Turning – up to 7 axis live tooling, bar feeder, and automated part management. Able to create quick-turn prototypes through full-rate production.

Full DCC Coordinate Measuring Machine (CMM) with scanning

Complete Quality Control Lab with calibrated tools per ISO17025, ANSI-Z540 calibration, and AS9102 FAIs capability.

Managed supply of various plating, inspection, testing, thermal, and other 2nd processes FAR, DFAR, FAA, FDA, DOT, ITAR, REACH & RoHS Compliance

DN Solutions DVF5000 GEN 2 5 Axis Mill

MILL

High-Performance Specs:

20,000 RPM, 42 HP HSK63 Spindle

High-Speed Machining: 1650 IPM Max Cutting Feed

Through Tool Air Blast

Through Tool High Pressure Coolant

X/Y/Z/C Axis cooling with linear glass scales for extreme accuracy and repeatability

Advanced Features:

8-Station Automated Pallet Pool

5-Axis Simultaneous Milling

Automatic Tool Setting Laser & Renishaw Probing

120-Tool Capacity

Part Capacity:

X=25.6”, Y=20.5”, Z=18.9”

Full 360° C-Axis & 140° B-Axis Tilt

Ideal for High Precision Prototypes and High-Volume High Precision Production

DN Solutions DVF6500T 5 Axis Mill Turn

MILL

High-Performance Specs:

20,000 RPM, 42 HP HSK63 Spindle

High-Speed Machining: 1650 IPM Max Cutting Feed

Through Tool Air Blast

Through Tool High Pressure Coolant

X/Y/Z/C Axis cooling with linear glass scales for extreme accuracy and repeatability

Advanced Features:

1,000 RPM Turning Capability

5-Axis Simultaneous Milling

Automatic Tool Setting Laser & Renishaw Probing

120-Tool Capacity

Part Capacity:

X=25.6”, Y=20.5”, Z=18.9”

Full 360° C-Axis & 140° A-Axis Tilt

Ideal for High Precision Prototypes and High-Volume High Precision Production

DN Solutions DNX 2100SB 7 Axis Mill Turn

MILL

High-Performance Specs:

12,000 RPM, 25 HP HSK63T Spindle

High-Speed Machining: 1650 IPM Max Cutting Feed

Through Tool Air Blast

Through Tool High Pressure Coolant

X/Y/Z/B Axis cooling with linear glass scales for extreme accuracy and repeatability

Advanced Features:

4,000 RPM Main Spindle Turning Capability

5,000 RPM Sub Spindle Turning Capability

Automatic Tool Setting Laser & Renishaw Probing

60-Tool Capacity

6-Axis Simultaneous Milling

Part Capacity:

Max Diameter= 21” Max Length= 43”

B-Axis 240°

Ideal for High Precision Prototypes and High-Volume High Precision Production

DN Solutions DNM5700 GEN 4

LATHE

High-Performance Specs:

15,000 RPM, 25 HP CAT40 Big Plus Spindle

High-Speed Machining: 1650 IPM Max Cutting Feed

Through Tool Air Blast

Through Tool High Pressure Coolant

Large Linear Roller Guides For Maximum Rigidity

Advanced Features:

Automatic Tool Setting Laser & Renishaw Probing

40-Tool Capacity

High Speed Controller With 200 Block Look Ahead

Massive Meehanite Cast Iron Bed

Part Capacity:

X=40” Y=22” Z=20”

Ideal for High Precision Prototypes and Heavy Duty Machining

DN Solutions Puma 2600YII

LATHE

High-Performance Specs:

4,000 RPM, 30HP, Ø3-3/16” Through Bore Spindle

High-Speed Machining: 120 IPM Max Rapid

Through Tool Air Blast

Through Tool 1,000 PSI High Pressure Coolant

Full C Axis Contouring Milling

X Axis Glass Scale

Advanced Features:

Automatic Tool Setting

24-Tool Capacity

5,000 RPM Live Tool Milling Spindle In Every Tool Position

Ø3” Capacity Bar Feeder

Rigid 30-degree one-piece cast-iron slant bed design with solid box way construction

Part Capacity:

Ø15” Diameter x 30” Length

Ideal for High Precision Turning and Production

Mitutoyo Crysta CMM

INSPECTION

Accuracy:

.00012” Repeatability

0.000004" Resolution

Advanced Features:

5 Axis Touch Probe

Tool Styli Changing Station

REVO 5 Axis Scanning Head

Kept in FOD Free and Climate Controlled Inspection Lab

Part Capacity:

X=27.5”, Y=40”, Z=23”

Zeiss Contura CMM

INSPECTION

Accuracy:

.00012” Repeatability

1,4 + L/350 µm

Advanced Features:

5 Axis Touch Probe

Tool Styli Changing Station

ZEISS VAST XXT 5 Axis Scanning Head

Kept in FOD Free and Climate Controlled Inspection Lab

Part Capacity:

X=900mm, Y=1800mm, Z=600mm

Mitutoyo 15” Optical

INSPECTION

Accuracy:

.0002” Repeatability

0.0001" Resolution

Advanced Features:

50x Magnification

Surface Illumination

DRO With X and Z Rotational Feedback

M3 Software

Kept in FOD Free and Climate Controlled Inspection Lab

Part Capacity:

Ø15”

HAAS UMC 500

MILL

15,000 RPM x 30 HP HSK Spindle

High Speed Machining

1200 IPM cutting speeds

2000 IPM RapidsThrough Tool High Pressure Coolant

20 Station Pallet Pool

5 Axis Milling

Automatic tool setter

Renishaw probing

70 + 1 tool carousel

X=20”, Y=16”, Z=16”

Full 360° C axis & 135° full tilt in B

Capable of complex prototyping or high efficiency in full rate production

Tsugami SS32

LATHE

200 – 8,000 RPM Spindle Speed

24/40 Tool Positions (std / max)

6 Axes

320 mm, 12.6” Stroke easily handles long pieces

Handles Complex Parts

Large Tool Zone

Fanuc 32i-B CNC

Change part runs quickly, handle long and short run jobs easily. Live tools moved at will!